Tandem and Tri-axle Semi Trailer Mechanical Suspensions with Leaf Spring

- 25+ years production experience

- Implementing IATF 16949-2016

- Implementing ISO 9001-2015

- Quality testing by an independent lab

- Warranty: 18 months since shipping date

- Sales volume (sets): 50,000+

- 95%+ self-produced parts

- Welding by automatic CNC robots/lines

- Quality claim rate: under 0.1%

- 98% on-time delivery

Applications

Semi-trailer suspensions serve as a critical component linking the running gear to the vehicle’s frame, ensuring seamless force transmission across all operational conditions. By mitigating road-induced vibrations and shocks, these systems safeguard cargo integrity, enhance vehicle stability, and optimize driver comfort during long-haul transport.

Their versatility extends across diverse trailer types, including skeletal trailers for containerized freight, lowbed designs for heavy machinery, flatbeds for versatile cargo, dump trailers for bulk materials, car carriers for automotive logistics, tankers for liquid transport, enclosed vans for temperature-sensitive goods, full trailers for combined loads, timber haulers for forestry products, and agricultural trailers for farm equipment.

Suspension systems are further categorized by design and functionality, encompassing German-engineered precision series, American-standard robust models, bogie/tandem axle configurations for weight distribution, air-ride suspensions for smoothness, rigid beam suspensions for durability, specialized YORK/ROR/HENRED variants, and agricultural-focused solutions tailored to rugged terrains and payload demands.

Features

| QC management system | Implementing IATF 16949-2016 |

|---|---|

| Services quality management system | Implementing ISO 9001-2015 |

| Warranty | 18 months since shipping date |

| Quality testing passed | An independent lab in China |

| Raw material for suspensions | Q235 from China's TOP-3 steel mills can achieve a longer life under higher loads |

| Steel plate cutting by | CNC Plasma Cutting Machines |

| Press forming by | 40-800 ton hydraulic press machines with hundreds of precision molds |

| Hanger welding by | Automatic CNC welding robots/lines with hundreds of precise fixture toolings |

| Smooth surface by | Shot-peening |

| Painting by | Automatic coating line |

| Producing leaf springs and casting parts by | Ourselves to ensure the lead time and quality are under control |

| Equalizer bushes | Using taper or greaseless powdered metal ones to be more durable |

| Arm bushes | Using natural rubber ones to be more durable |

| Adjustable arms screw by | Galvanized anti-rust treatment |

| Sets of annual output | 50,000+ |

| Overseas market | 30+ countries (Austraulia, Polland, Russia, Brazil, Mexico, Thailand, Malaysia, Singapore, Vietnam, The Philippines, Indonesia, Bolivia, Argentina, Chile, Peru, Guatemala, Panama, Egypt, South Africa, Nigeria, Tanzania, etc.) |

| Clients (overseas) | 100+ |

| Land area (square meters) | 18,000+ |

| Number of equipments (sets) | 200+ |

| Employees | 120+ |

| Engineers | 12+ |

| Available certificates | COC, PVOC, CIQ, SONCAP, C/O, FORM E, FORM A. |

Comprehensive Info of Suspensions:

| uspension types | German series suspensions, American series suspensions, bogie/boogie suspension series, air suspension series, rigid suspension series, YORK suspensions, ROR suspensions, HENRED suspensions, semi-trailer suspensions, trailer suspensions and agricultural series, etc. |

|---|---|

| Interchangeable brands | BPW suspensions, FUWA suspension, YORK suspensions, ROR suspensions, HENRED suspensions. |

| Replacements | FW880201A, FW880202A, FW880203A, FW880201B, FW880202B, FW880203B, FW880301A, FW880302A, FW880303A, FW880301B, FW880302B, FW880303B, FW860201A, FW860202A, FW860203A, FW860201B, FW860202B, FW860203B, FW860301A, FW860302A, FW860303A, FW860301B, FW860302B, FW860303B, FW86.2/1310/250/BQ6/9, FW86.2/1360/250/BQ6/9, FW86.3/1310/250/BQ6/9, FW86.3/1360/250/BQ6/9. |

| Quantity of installed axles including | 1-axle suspensions, 2-axle suspensions, 3-axle suspensions, 4-axle suspensions, etc. |

| Position of installed axles including | Overslung & underslung suspensions |

| Type of installed axle beams including | Square & round axle beam suspensions |

| Hanger thickness | 6 mm, 8 mm, 10 mm |

| Equalizer thickness | 8 mm, 10 mm, 12 mm |

| Equalizer pin diameter | 50 mm, 60 mm, 70 mm |

| Axis (torque arm pin) diameter | 28 mm, 36 mm |

| Arm bushes | Natural rubber, composite bushings, urethane rubber, used rubber, etc. |

| Leaf springs | 90x16x7 leaves, 90x16x9 leaves, 100x16x10 leaves, 100x12x12 leaves, 100x12x14 leaves, 100x14x12 leaves, 75x13x8 leaves, 75x13x9 leaves, 75x14x8 leaves, 75x14x9 leaves, etc. |

| Colors | Red, black, grey, blue, etc. |

| Optional parts/components | Front hangers, rear hangers, center hangers, equalizers, equalizer pins, equalizer bushes, brackets, axle seats, axises, bushes, leaf springs, U-bolts, bolts, fixed arms, adjustable arms, hanger spacers, reinforcing plates, reinforcing brackets for equalizers, etc. |

| Package | * 30 sets~35 sets of suspensions with leaf springs in one 20 ft container; |

| * 60 sets~70 sets of suspensions without leaf spring in one 20 ft container; | |

| * Mixed load with other trailer parts. | |

| Standards implemented | IATF 16949-2016, ISO 9001-2015. |

| Payment | TT, LC, DP. |

| Lead time | About 10~15 working days |

| MOQ | 1 set |

Parameters

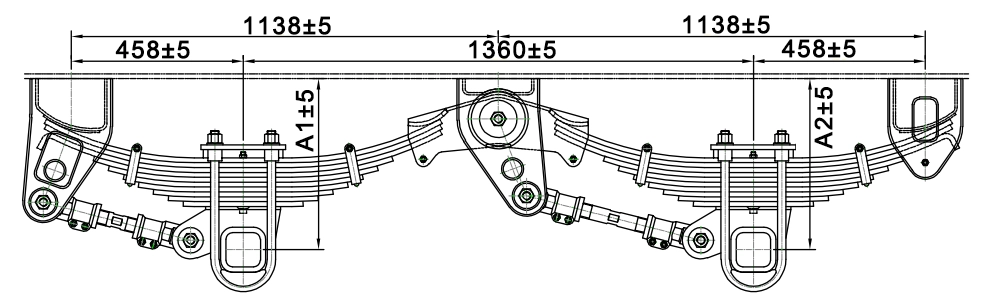

American Type Suspension Series:

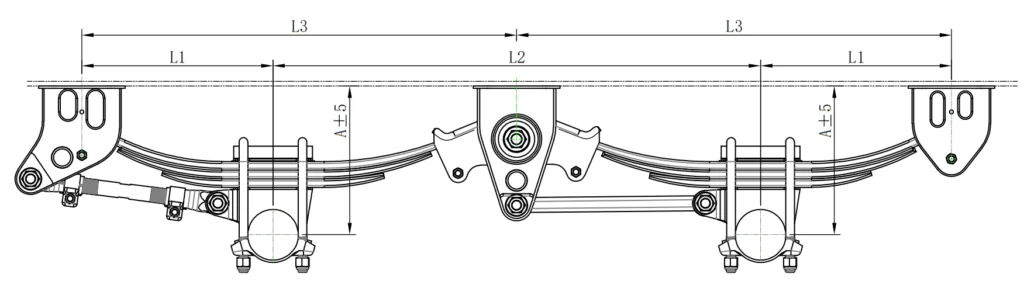

-GW13 Type Suspension Series

| GW13.01 Tandem (2-axle) Suspensions | |||||

|---|---|---|---|---|---|

| Model | Height of towing plate (mm) | A1 (mm) | A2 (mm) | H (mm) | Axle Loading (kg) |

| GW13.01.2001 | 1180 | 441 | 433 | 183 | 13,000 * 2 |

| GW13.01.2002 | 1220 | 481 | 473 | 223 | 13,000 * 2 |

| GW13.01.2003 | 1250 | 511 | 503 | 253 | 13,000 * 2 |

| GW13.01.2004 | 1180 | 422 | 414 | 164 | 13,000 * 2 |

| GW13.01.2005 | 1220 | 462 | 454 | 204 | 13,000 * 2 |

| GW13.01.2006 | 1250 | 492 | 484 | 234 | 13,000 * 2 |

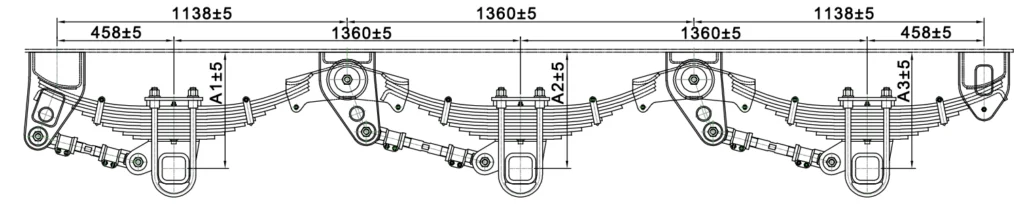

| GW13.02 Tri (3-axle) Suspensions | ||||||

|---|---|---|---|---|---|---|

| Model | Height of towing plate (mm) | A1 (mm) | A2 (mm) | A3 (mm) | H (mm) | Axle Loading (kg) |

| GW13.02.2001 | 1180 | 457 | 448 | 435 | 185 | 13,000 * 3 |

| GW13.02.2002 | 1220 | 497 | 488 | 475 | 225 | 13,000 * 3 |

| GW13.02.2003 | 1250 | 527 | 518 | 505 | 255 | 13,000 * 3 |

| GW13.02.2004 | 1180 | 438 | 429 | 416 | 166 | 13,000 * 3 |

| GW13.02.2005 | 1220 | 478 | 469 | 456 | 206 | 13,000 * 3 |

| GW13.02.2006 | 1250 | 508 | 499 | 486 | 236 | 13,000 * 3 |

Note:

(1) Demension “A1, A2, A3”: unladen

(2) Suitable for round/square axles

(3) Suggested leaf spring: 90×16×7 pcs

-GW16 Type Heavy Duty Suspension Series

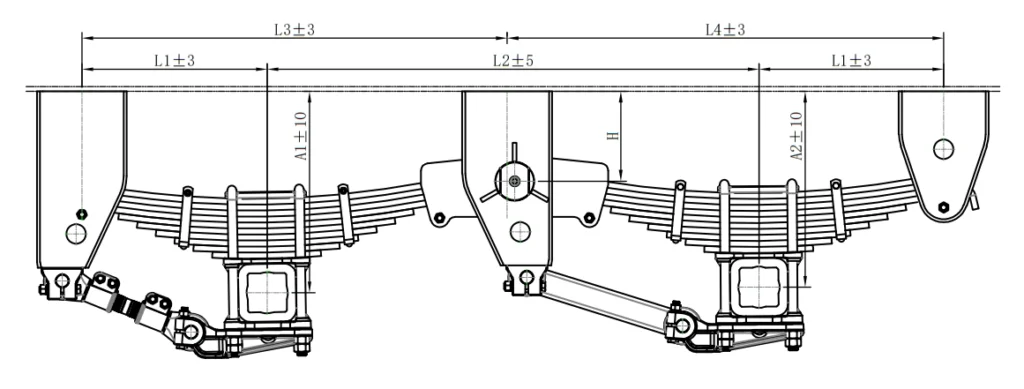

| GW16.01 Tandem (2-axle) Suspensions | |||||

|---|---|---|---|---|---|

| Model | Height of towing plate (mm) | A1 (mm) | A2 (mm) | H (mm) | Axle Loading (kg) |

| GW16.01.2001 | 1180 | 473 | 465 | 183 | 16,000 * 2 |

| GW16.01.2002 | 1220 | 513 | 505 | 223 | 16,000 * 2 |

| GW16.01.2003 | 1250 | 543 | 535 | 253 | 16,000 * 2 |

| GW16.01.2004 | 1180 | 454 | 446 | 164 | 16,000 * 2 |

| GW16.01.2005 | 1220 | 494 | 484 | 204 | 16,000 * 2 |

| GW16.01.2006 | 1250 | 526 | 518 | 234 | 16,000 * 2 |

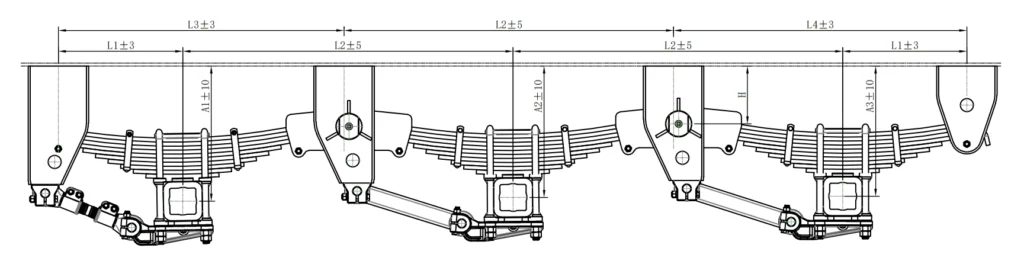

| GW16.02 Tri (3-axle) Suspensions | ||||||

|---|---|---|---|---|---|---|

| Model | Height of towing plate (mm) | A1 (mm) | A2(mm) | A3 (mm) | H (mm) | Axle Loading (kg) |

| GW16.02.2101 | 1180 | 489 | 480 | 467 | 183 | 16,000 * 3 |

| GW16.02.2102 | 1220 | 529 | 520 | 507 | 223 | 16,000 * 3 |

| GW16.02.2103 | 1250 | 599 | 550 | 537 | 253 | 16,000 * 3 |

| GW16.02.2104 | 1180 | 470 | 461 | 448 | 164 | 16,000 * 3 |

| GW16.02.2105 | 1220 | 510 | 501 | 588 | 204 | 16,000 * 3 |

| GW16.02.2106 | 1250 | 540 | 531 | 518 | 234 | 16,000 * 3 |

Note:

(1) Demension “A1, A2, A3”: unladen

(2) Suitable for round/square axles

(3) Suggested leaf spring: 90×16×9 pcs

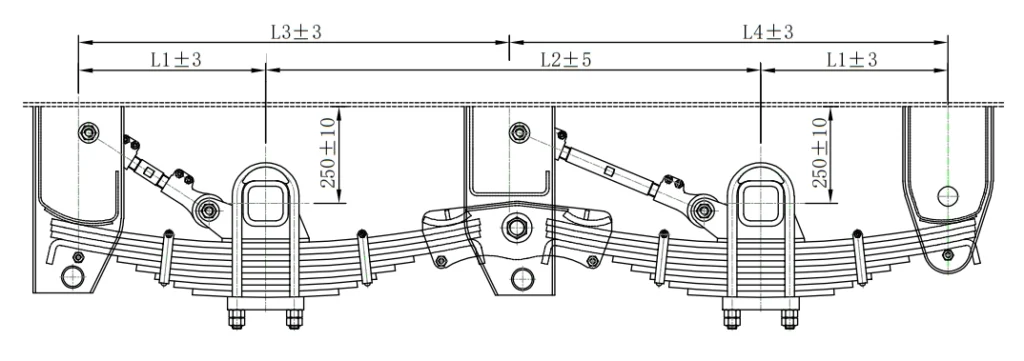

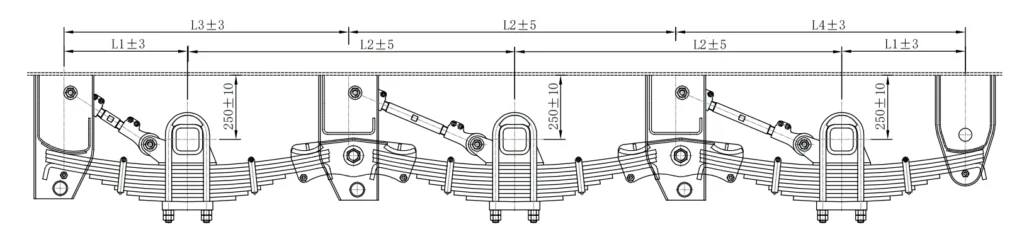

-GW16 Type Heavy Duty Underslung Suspension Series

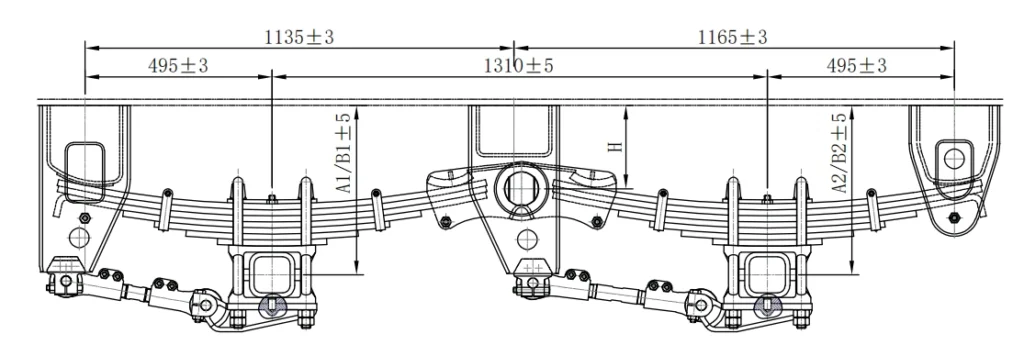

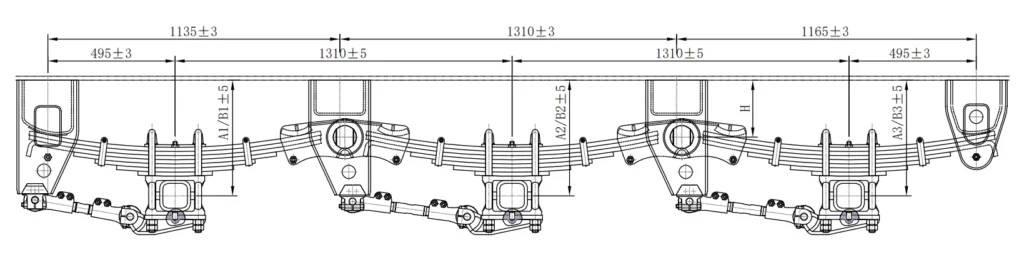

| GW16.03 Tandem (2-axle) Underslung Suspensions | |||||

|---|---|---|---|---|---|

| Model | L1 (mm) | L2 (mm) | L3 (mm) | L4 (mm) | Axle Loading (kg) |

| GW16.03.2201 | 495 | 1310 | 1135 | 1165 | 16,000 * 2 |

| GW16.03.2202 | 495 | 1360 | 1160 | 1190 | 16,000 * 2 |

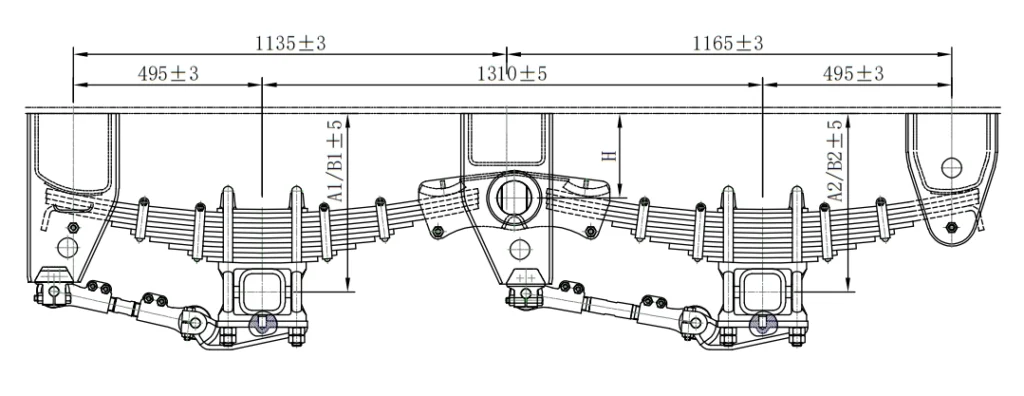

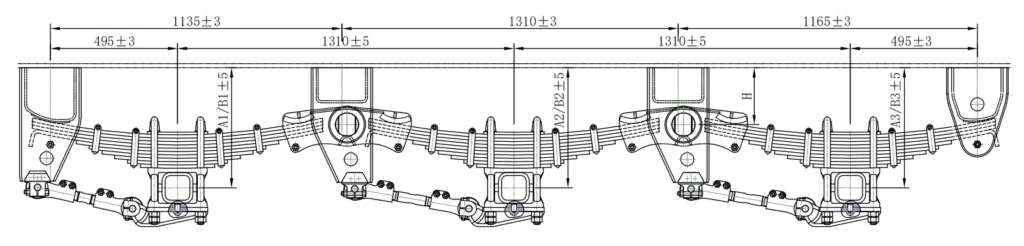

| GW16.04 Tandem (2-axle) Underslung Suspensions | |||||

|---|---|---|---|---|---|

| Model | L1 (mm) | L2 (mm) | L3 (mm) | L4 (mm) | Axle Loading (kg) |

| GW16.04.2301 | 495 | 1310 | 1135 | 1165 | 16,000 * 2 |

| GW16.04.2302 | 495 | 1360 | 1160 | 1190 | 16,000 * 2 |

Note:

(1) Suitable for round/square axles

(2) Suggested leaf spring: 90×16×9 pcs

-GW11 Type Stamping Suspension Series

| GW11.01 AR5 Tandem (2-axle) Suspensions | |||

|---|---|---|---|

| Model | A1 (mm) | A2 (mm) | Axle Loading (kg) |

| GW11.01.3001 | 440 | 440 | 11,000 * 2 |

| GW11.01.3002 | 415 | 415 | 11,000 * 2 |

| GW11.01.3003 | 390 | 390 | 11,000 * 2 |

| GW11.01.3004 | 440 | 415 | 11,000 * 2 |

| GW11.01.3005 | 415 | 390 | 11,000 * 2 |

| GW11.02 AR5 Tri (3-axle) Suspensions | ||||

|---|---|---|---|---|

| Model | A1 (mm) | A2 (mm) | A3 (mm) | Axle Loading (kg) |

| GW11.02.2010 | 440 | 440 | 440 | 16,000 * 2 |

| GW11.02.2011 | 415 | 415 | 415 | 16,000 * 2 |

| GW11.02.2012 | 390 | 390 | 390 | 16,000 * 2 |

| GW11.02.2013 | 440 | 415 | 390 | 16,000 * 2 |

Note:

(1) Demension “A1, A2, A3”: unladen

(2) Suitable for round/square axles

(3) Suggested leaf spring: 75×13×8 pcs

-GW10 Type Lightweight Suspension Series

| GW10.01 AR5 Tandem (2-axle) Underslung Suspensions | |||||

|---|---|---|---|---|---|

| Model | A1 (mm) | L1 (mm) | L2 (mm) | L3 (mm) | Axle Loading (kg) |

| GW10.01.1001 | 390 | 482.5 | 1245 | 1105 | 10,000 * 2 |

| GW10.01.1002 | 415 | 482.5 | 1245 | 1105 | 10,000 * 2 |

| GW10.01.1003 | 440 | 482.5 | 1245 | 1105 | 10,000 * 2 |

Note:

(1) Demension “A1, A2, A3”: unladen

(2) Suitable for round/square axles

(3) Suggested leaf spring: 75×22×3 pcs

-GW20 Type Heavy Duty Suspension Series

| GW20.01 Tandem (2-axle) Suspensions | |||||

|---|---|---|---|---|---|

| Model | Height of towing plate (mm) | A1 (mm) | A2 (mm) | H (mm) | Axle Loading (kg) |

| GW20.02.2001 | 1180 | 489 | 481 | 183 | 20,000 * 2 |

| GW20.02.2002 | 1220 | 529 | 521 | 223 | 20,000 * 2 |

| GW20.02.2003 | 1250 | 559 | 551 | 253 | 20,000 * 2 |

| GW20.02.2004 | 1180 | 470 | 462 | 164 | 20,000 * 2 |

| GW20.02.2005 | 1220 | 510 | 502 | 204 | 20,000 * 2 |

| GW20.02.2006 | 1250 | 540 | 532 | 234 | 20,000 * 2 |

| GW20.02 Tri (3-axle) Suspensions | ||||||

|---|---|---|---|---|---|---|

| Model | Height of towing plate (mm) | A1 (mm) | A2 (mm) | A3 (mm) | H (mm) | Axle Loading (kg) |

| GW20.02.2001 | 1180 | 505 | 496 | 483 | 183 | 20,000 * 3 |

| GW20.02.2002 | 1220 | 545 | 536 | 523 | 223 | 20,000 * 3 |

| GW20.02.2003 | 1250 | 575 | 566 | 553 | 253 | 20,000 * 3 |

| GW20.02.2004 | 1180 | 486 | 477 | 464 | 164 | 20,000 * 3 |

| GW20.02.2005 | 1220 | 526 | 517 | 504 | 204 | 20,000 * 3 |

| GW20.02.2006 | 1250 | 556 | 547 | 534 | 234 | 20,000 * 3 |

Note:

(1) Demension “A1, A2, A3”: unladen

(2) Suitable for round/square axles

(3) Suggested leaf spring: 100×16×10 pcs

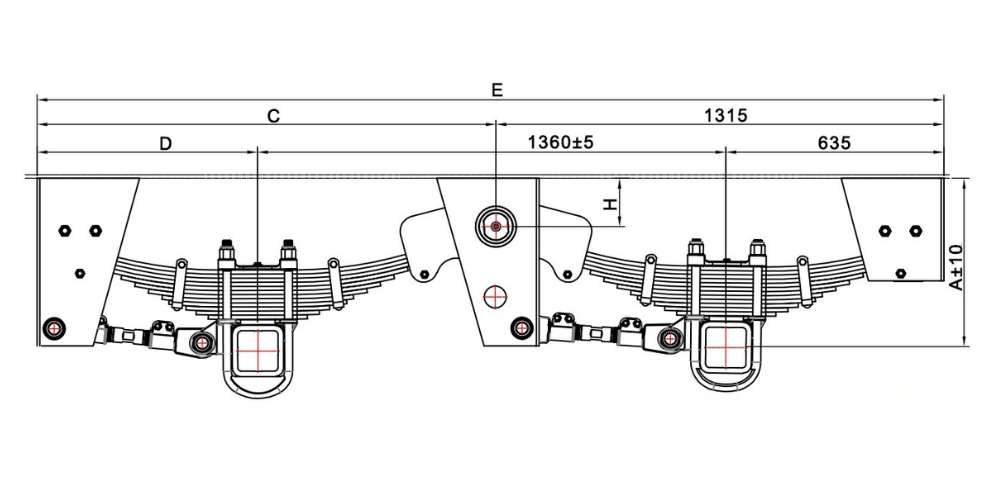

German type Suspension Series

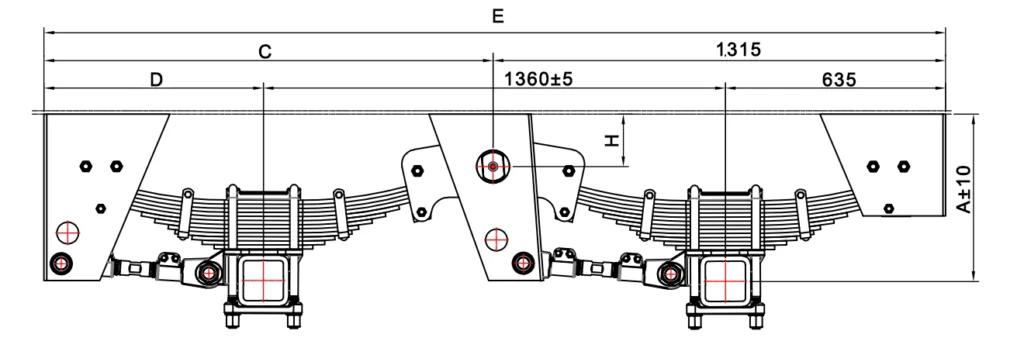

| GWG01 Tandem (2-axle) Suspensions | ||||||

|---|---|---|---|---|---|---|

| Model | H (mm) | A (mm) | C (mm) | D (mm) | E (mm) | Leaf spring |

| GWG01.10.2001 | 155 | 490 | 1295 | 615 | 2610 | 100×12×12 |

| GWG01.10.2002 | 155 | 514 | 1295 | 615 | 2610 | 100×12×14 |

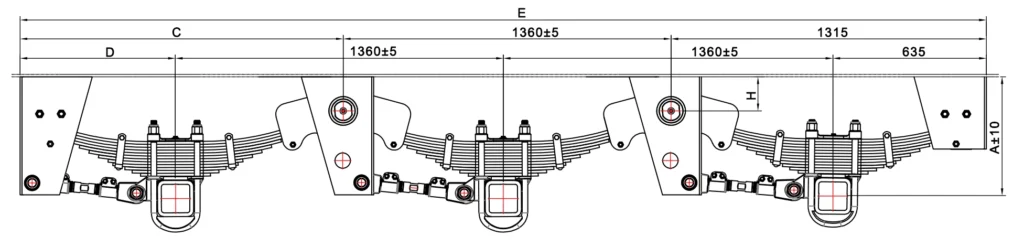

| GWG02 Tri (3-axle) Suspensions | ||||||

|---|---|---|---|---|---|---|

| Model | H (mm) | A (mm) | C (mm) | D (mm) | E (mm) | Leaf spring |

| GWG02.10.2001 | 155 | 490 | 1295 | 615 | 3970 | 100×12×12 |

| GWG02.10.2002 | 155 | 514 | 1295 | 615 | 3970 | 100×12×14 |

Note:

(1) Demension “A”: unladen

(2) Suitable for round/square axles

(3) Suggested leaf spring: 100×12×12 pcs, 100×14×12 pcs, 100×12×14 pcs

| GWG03 Tandem (2-axle) Suspensions | ||||||

|---|---|---|---|---|---|---|

| Model | H (mm) | A (mm) | C (mm) | D (mm) | E (mm) | Leaf spring |

| GWG03.10.2001 | 155 | 500 | 1295 | 615 | 2610 | 100×12×12 |

| GWG03.10.2002 | 155 | 524 | 1295 | 615 | 2610 | 100×12×14 |

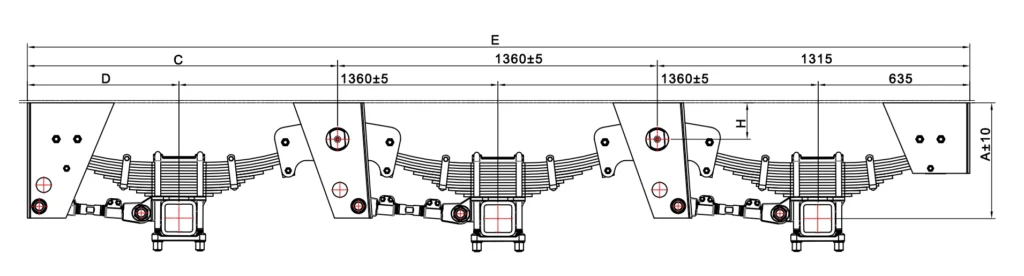

| GWG04 Tri (3-axle) Suspensions | ||||||

|---|---|---|---|---|---|---|

| Model | H (mm) | A (mm) | C (mm) | D (mm) | E (mm) | Leaf spring |

| GWG04.10.2001 | 155 | 500 | 1295 | 615 | 2610 | 100×12×12 |

| GWG04.10.2002 | 155 | 524 | 1295 | 615 | 2610 | 100×12×14 |

Note:

(1) Demension “A”: unladen;

(2) Suitable for round/square axles

(3) Suggested leaf spring: 100×12×12 pcs, 100×14×12 pcs, 100×12×14 pcs